In industrial production, consumer goods, and advanced chemical systems, many failures trace back to one invisible issue: interfaces that refuse to cooperate. Oils do not mix with water, powders clump instead of dispersing, coatings bead instead of spreading, and soils reattach instead of washing away. These interfacial problems increase costs, reduce performance, and shorten product life. The solution, across nearly every sector, is the controlled use of surfactants to manage how different phases interact.

A surfactant’s role is to reduce interfacial tension and control interactions between immiscible phases—such as oil, water, solids, and gases—enabling wetting, emulsification, dispersion, detergency, foaming, or defoaming in a predictable and functional way.

Once this role is understood at a molecular and system level, surfactants stop being “additives” and become core functional components that determine whether a formulation works or fails.

The fundamental role of surfactants at interfaces

At its core, a surfactant is an interface manager. Every system involving liquids, solids, or gases has interfaces where surface energy dominates behavior. High interfacial tension creates resistance to spreading, mixing, and adhesion. Surfactants lower this energy barrier, making otherwise unfavorable interactions possible.

Molecularly, surfactants are amphiphilic. One part of the molecule prefers nonpolar environments, while the other prefers polar environments. When added to a system, surfactants migrate spontaneously to interfaces and orient themselves in a way that stabilizes the system. This single mechanism underpins all surfactant functions, regardless of industry or application.

Wetting: enabling contact where it otherwise fails

One of the most critical roles of a surfactant is wetting. Wetting determines whether a liquid spreads across a solid surface or beads up and retreats. In coatings, inks, agrochemicals, cleaners, and adhesives, poor wetting leads to uneven coverage, defects, and wasted material.

By lowering the surface tension of the liquid and modifying solid–liquid interfacial energy, surfactants allow liquids to penetrate pores, spread uniformly, and maintain contact long enough to perform their function. Without surfactants, many industrial processes—such as fiber treatment, pigment coating, or precision cleaning—would be impractical at scale.

Emulsification: stabilizing oil–water systems

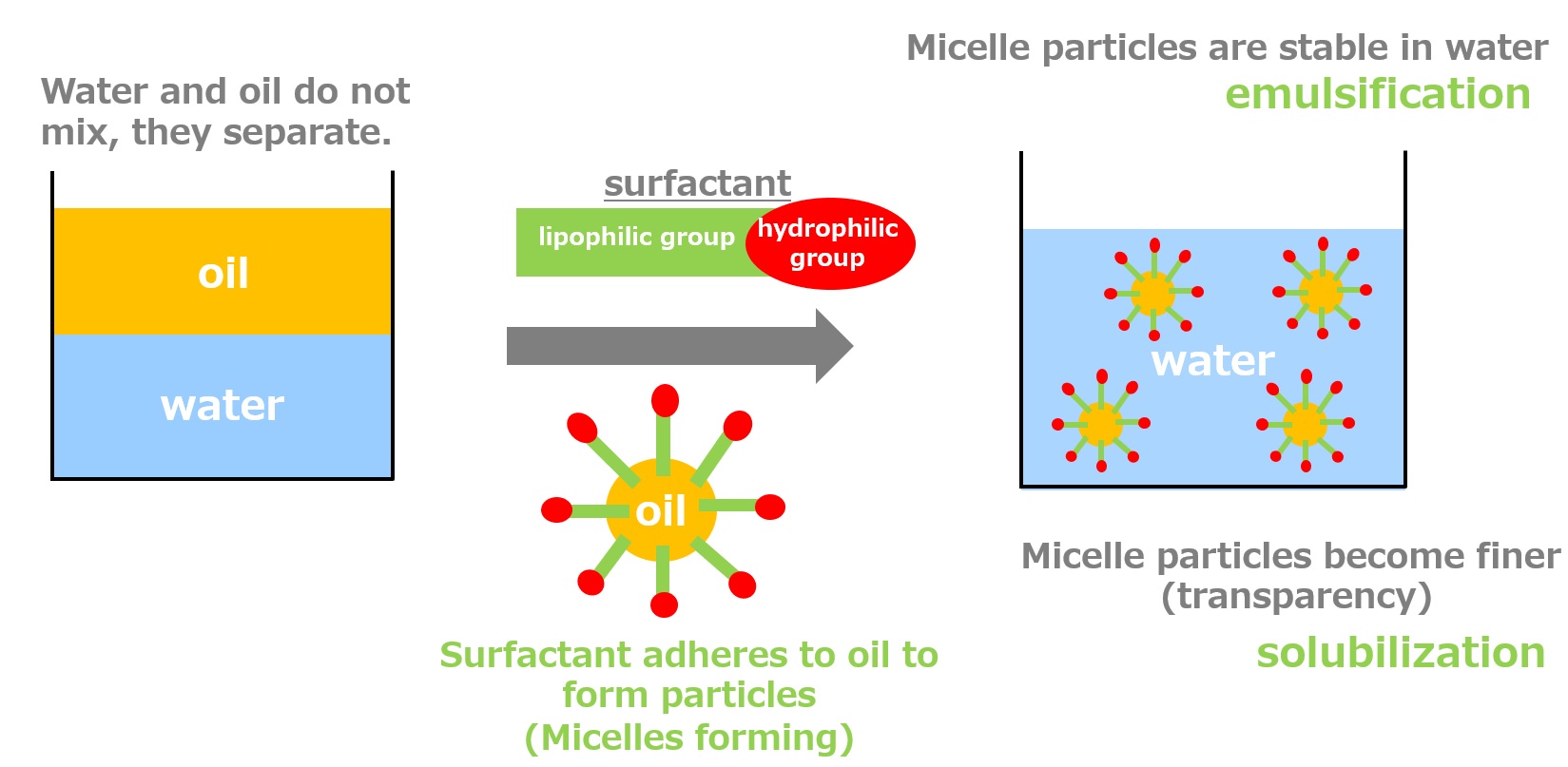

Another central role of surfactants is emulsification, the stabilization of mixtures between immiscible liquids such as oil and water. In an emulsion, surfactant molecules form a protective barrier around dispersed droplets, preventing them from coalescing and separating.

This function is foundational in foods, cosmetics, pharmaceuticals, agrochemicals, lubricants, and polymer emulsions. The surfactant does not merely “mix” the liquids; it defines droplet size, stability over time, temperature tolerance, and resistance to mechanical stress. In many formulations, changing the surfactant system has a greater impact than changing the active ingredient itself.

Detergency: removing and suspending soils

In cleaning systems, surfactants play a dual role. First, they reduce the adhesion between soils and surfaces, allowing contaminants to detach. Second, they encapsulate and suspend the removed soils in the wash liquid, preventing redeposition.

This is achieved through micelle formation, where surfactant molecules aggregate with hydrophobic cores that trap oils and greases. The effectiveness of detergency depends on surfactant type, concentration, temperature, water quality, and mechanical action. Without surfactants, water alone is largely ineffective against oily or particulate contamination.

Core surfactant functions and outcomes

| Function | Interface controlled | Practical outcome |

|---|---|---|

| Wetting | Liquid–solid | Uniform spreading, penetration |

| Emulsification | Liquid–liquid | Stable oil–water systems |

| Detergency | Solid–liquid | Soil removal and suspension |

| Dispersion | Solid–liquid | Stable particle distribution |

| Foaming / defoaming | Gas–liquid | Controlled air incorporation |

Dispersion: controlling solid particles

In systems containing powders or pigments, surfactants act as dispersing agents. Their role is to prevent particles from agglomerating and settling. By adsorbing onto particle surfaces, surfactants create repulsive forces—electrostatic, steric, or both—that keep particles evenly distributed.

This role is critical in paints, inks, ceramics, battery slurries, construction materials, and polymer composites. Poor dispersion leads to inconsistent performance, mechanical weakness, and visual defects. Effective surfactant selection directly influences product reliability and shelf stability.

Foaming and defoaming: managing gas–liquid interfaces

Surfactants also control how gases interact with liquids. Some surfactants stabilize foam by strengthening the liquid film around air bubbles, while others actively destabilize foam by disrupting that film. Whether foam is desirable or problematic depends entirely on the application.

In firefighting, flotation, food processing, and personal care, controlled foam is essential. In chemical reactors, coating lines, and wastewater treatment, foam is often a liability. In both cases, surfactants define the behavior of the system.

Compatibility and system-level performance

Beyond individual functions, surfactants play a system-level role as compatibility agents. They enable otherwise incompatible ingredients—oils, polymers, salts, enzymes, actives—to coexist in a stable formulation. This role becomes increasingly important as formulations grow more complex and performance expectations rise.

Modern surfactant systems are rarely chosen for a single function. Instead, they are selected to balance wetting, stability, detergency, environmental profile, and cost within real operating constraints.

Surfactant role by industry

| Industry | Primary surfactant role |

|---|---|

| Detergents & cleaners | Soil removal, wetting |

| Coatings & inks | Wetting, dispersion |

| Agrochemicals | Emulsification, spreading |

| Food & cosmetics | Emulsion stability |

| Electronics & precision cleaning | Controlled wetting, low residue |

Why surfactants are formulation-critical, not optional

A common misconception is that surfactants are secondary ingredients. In practice, they often define whether a product works at all. Active ingredients deliver function, but surfactants determine delivery, stability, and usability. This is why surfactant selection is one of the earliest and most consequential decisions in formulation development.

Replacing or removing a surfactant without redesigning the system typically results in unpredictable failures. Experienced formulators treat surfactants as structural components of the formulation architecture.

Final perspective

The role of a surfactant is not limited to “making things mix.” It is to engineer interfaces, reduce energetic barriers, and create controlled, repeatable interactions between phases that would otherwise resist each other. From cleaning a surface to stabilizing a pharmaceutical emulsion, surfactants quietly determine success.

Understanding this role at a fundamental level allows engineers, buyers, and decision-makers to move beyond trial-and-error and toward rational, performance-driven formulation design.

A note from practical industry experience

In real industrial systems, surfactant problems rarely announce themselves clearly. They appear as instability, inconsistency, or unexplained performance loss. In most cases, these issues are not solved by adding more surfactant, but by choosing the right type for the right interfacial problem.

Talk to Sparrow-Chemical about surfactant solutions

If you are developing, optimizing, or sourcing surfactants for industrial, specialty, or performance-critical applications, Sparrow-Chemical provides application-focused technical support and reliable global supply. We help customers understand not just what surfactant to use, but why it works in their system. Visit https://sparrow-chemical.com/ to discuss your application with our technical team.